Filtration and separation specialist passing on a rich global environment to future generations

Reduce Reuse Recycle

Services

TOMS

TOMS provides solutions for issues of oil management, and tackles the Sustainable Development Goals (SDGs) by offering three suggestions.

Total Oil Maintenance Service (TOMS) proposed by Triple R Group

Products

BU series

| BU30E | BU100E | BU300E | BU200E |

The series is the precise filtration device for small hydraulic equipment.

The devices also adsorb and remove moisture with the dedicated elements.

They are bleed-off type utilizing power of equipment.

SE/SS series

| SE100-ST | SU102-YT |

The series is the precise filtration device for small hydraulic equipment.

Applicable to different types of oil including lubricant.

The devices also adsorb and remove moisture with the dedicated elements.

They are equipped with the small pump motor, and can always operate recirculation filtration.

OSCA series

| SS type | AL type | SU type |

| WS-WD type | OS type |

The series is the precise filtration device for medium and large hydraulic equipment.

Applicable to different types of oil including lubricant.

The devices adsorb and remove moisture with the dedicated elements.

They are equipped with the pump motor, and can always operate recirculation filtration.

Vacuum water removal device series

TRVS-30E

The series is the water removal device for medium and large oil (concentration) tank.

It keeps moisture content of high viscosity lubricant at 500 ppm, and remove dissolved water.

The device is equipped with the pump motor, and can always operate recirculation filtration.

Centrifuge series

| TRS-50M-PM | TRS-80M-PM |

It captures foreign substance generated in the coolant liquid (oil) of various machine tools, and also captures non-magnetic materials such as abrasive particles.

The consumable parts like filters are not necessary due to separation by centrifugal force.

The captured objects can be removed from rotor and discarded easily.

The device is equipped with the pump motor, and can always operate recirculation filtration.

Cyclone series

* TRCL-30L/50L-(P) (option)

The device separates foreign matters generated in coolant used in various machine tools, and further separates non‐magnetic materials including abrasive grain particles.

The consumable parts like filters are not necessary due to separation by centrifugal force.

The drain discharge is carried out for the separated objects as contaminated concentrate.

Magnetic separator series

* TRPMG-300L(K) (option)

The device adsorbs magnetic materials generated in coolant used in various machine tools.

The magnet height can be aligned to liquid level height, and microscopic iron powder floating in a tank is captured. The running cost is zero by permanent magnet.

Quicktron series

TRQT-50/100

The bubble having a negative influence on hydraulic equipment is removed.

The elements show the sufficient filter abilities by attaching them to OSCA to remove bubble.

Element series

They are Triple R dedicated precise filtration elements.

We offer various sizes and precision of our product lineup at a low price.

Filter series

We offer various sizes and precision of our product lineup for a variety of applications.

Introduction case

Filtration and purification device for grinder and polisher

Filtration device for reusing various oils

Filtration and purification device for steel sheet cleaning

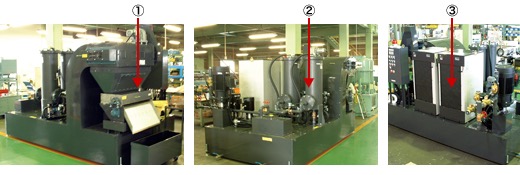

Filtration and purification device for grinder and polisher

Benefits of introduction

・ Reduce product defect, and reduce sludge containing oil discharged significantly.

・ Reduce tank cleaning works, and extend life of oil and water-soluble coolant.

Outline

① Magnet conveyor: remove a large amount of magnetic contamination.

② Back washing filter: capture contamination the magnet missed to capture.

⇒Currently, offer another device.

③ Oil controller (Oil temperature control device): option for precise temperature control of working oil.

Reduce product defect, and reduce sludge containing oil discharged significantly.

Reduce tank cleaning works, and extend life of oil and water-soluble coolant.

* Oil cleaner or filter

option for more precise filtration

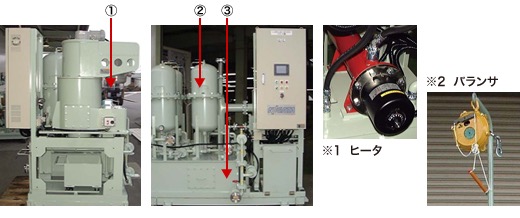

Filtration device for reusing various oils

Benefits of introduction

・ Reuse lubricant handled as waste oil among oil leakage including lubricant, ATF of each production line.

Outline

① Full automatic centrifuge:

remove a large amount of contamination (magnetic and non‐magnetic materials).

② SS305-H114: capture contamination including moisture centrifuge missed.

(Filtration accuracy: selectable up to 3µm)

③ conditioning tank: 200L

*1 Heater: option necessary for improving filtration efficiency of centrifuge by heating high viscosity working oil

*2 Balancer: option for towing and holding the cover of heavy load for when replacing elements

Filtration and purification device for steel sheet cleaning

Benefits of introduction

・ Prevent flaw (dirt sliver) in steel sheet cleaning line during press processing.

・ Prevent the damage of mold.

Outline

◯ Large capacity high precision filtration device (improving NAS grade using high precision element)

CS-SS327-1R+TANK-Unit-4300

◯ Using high efficiency pump

◯ Preprocessing: pipe magnet

Construction machine

Benefits of introduction

・ Filter contamination of hydraulic fluid without power by branching from the pilot line of the construction machine.

Outline

◯BU100E(2.0L/min)

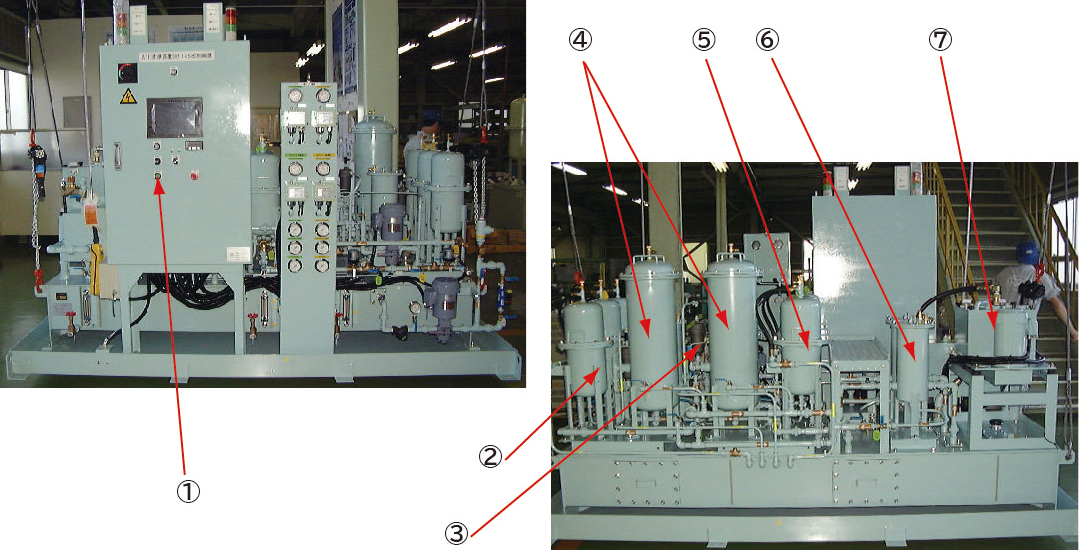

Oil cleaning device for tester line

Benefits of introduction

・ Improve the reuse and cleanliness of test oil for tester line includng ATF・CVT.

Outline

① Electric control board

② Oil cleaner SS103-H114

③ Quicktron

④ Prefilter SS6PF20

⑤ Oil cleaner SS103-H114

⑥ Suction filter

⑦ Manual centrifuge TRS-50M

Magnet barrier system

Benefits of introduction

・ Microscopic contaminating particles in hydraulic oil and lubricant are forced to flocculate and precipitate by passing them through unique effective field.

・ Enable to design for various tank shapes using a variety of "Magnetic separator".

・ Adsorb microscopic floatable contamination by adding the magnet at the intermediate part in oil.

Outline

Triple R Co., Ltd.

TR Bldg, 6-27-10 Ayase, Adachi-ku, Tokyo

Tel: +81-3-5616-7731