① TOP

Filtration and separation specialist passing on a rich global environment to future generations

Reduce Reuse Recycle

How to replace our elements

We offer series of elements, which can convert the consumable hydraulic oil into new resources. Our elements can maintain the cleanliness of new oil by periodical replacement.

You can recognize the condition of hydraulic oil at the replacement of elements.

ELEMENT REPLACEMENTS(SE・BU・AL)

ELEMENT REPLACEMENTS(SE・BU・AL)

*Please also exchange packing set (Rubber packing & Bonded-seal ) simultaneously at the time of replacement of an element.

①Shut off power to machine and oil cleaner pump.

②Loosen T-bolt (anticlockwise) and remove the lid and the rubber packing.

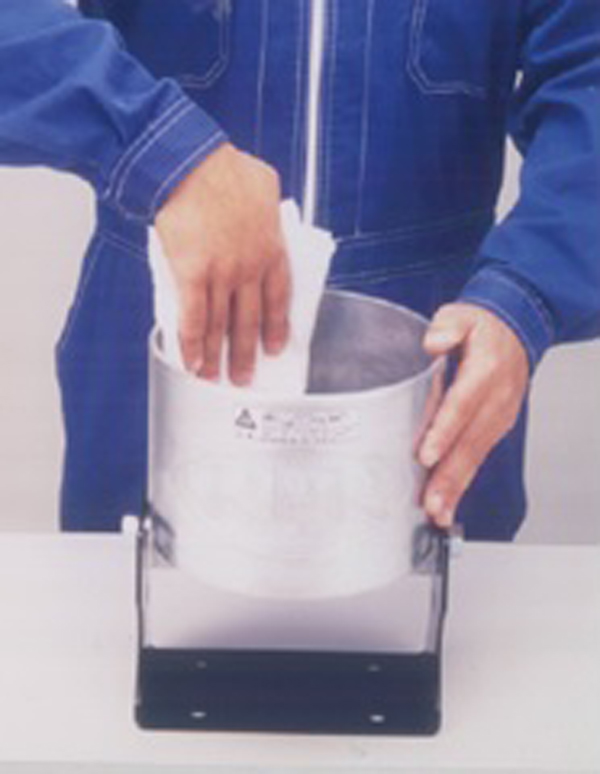

③Cover the housing with a vinyl bag, hold the fabric band, and pull out the element.

④Wipe off sludge and metal powders, etc. in the housing.

⑤Insert a new element. Push it in hard until the bottom edges of the housing dig into it.

⑥Spread some oil on the packing and fit it on the housing rim. Ensure that it fits into the lid's groove when you replace the lid.

⑦Replace the lid and the bonded-seal and tighten the T-bolt (clockwise) firmly. Turn on the power.

ELEMENT CHANGE(V-Band・SU)

*Please also exchange O-ring set (O-ring, spacer) simultaneously at the time of exchange of an element.

①Stop the operation.

②After confirming no residual oil/pressure, loosen the nut of V band coupling (counterclockwise) and remove V band and cap.

③Loosen the bracing nut (anticlockwise) and remove it.

④Pull out elements and cartridge Keep the cartridge with you.

⑤Wipe off sludge and metal powders, etc. in the housing.

⑥Replace new elements in cartridge and insert them in the housing. Tighten the bracing nut (clockwise). Spread some oil on the O-ring and fit it on the housing rim.

⑦Place the cap and V-band coupling. Tighten the V-band coupling nut (clockwise). Completely open the stop valve (anticlockwise), and ensure that there is no oil leakage.

ELEMENT CHANGE(SS305)

*Please exchange O rings at the same time when you exchange elements.

①Stop the operation.

②Make sure there is no residue oil and pressure, then remove M22 bolt to open the housing cap.

③The suppression nut is detached and suppression loosening (left rotation) the nut is detached with the wrench. The element (5 pieces) is taken out. The cartridge and the element come off on earth.

④A sludge and a metallic powder, etc. in the housing are cleaned with waste cloth etc.

⑤After some oil is spread, O ring is loaded into the housing.

⑥ Please attach the element to the cartridge. Grasp the round rod handle of the cartridge from the inside to the outside as not your fingers to be caught in the gap of the housing. Then, insert cartridges into the center shaft of the housing.

⑦Cover with the cap, and tighten the bolt of M22.

Triple R Co., Ltd.

TR Bldg, 6-27-10 Ayase, Adachi-ku, Tokyo

Tel: +81-3-5616-7731